- Home

- About

- Services

- Project Freight Forwarding

- Over Dimensional Inland Movements

- Early Logistics Engineering & Modularization Support

- Project Freight Budgets Estimating

- Single Source Logistics Provider

- Container Shipping Operations

- Worldwide Forwarder Logic

- Vessel Chartering Operations

- Air Freight Forwarding Services

- Inland Freight - LTL / FTL

- Marine Insurance Agent

- Arranging Customs Clearance

- VAT Consulting

- Events

- Tools

- Quality

- Safety

- Contact

- Quote Request

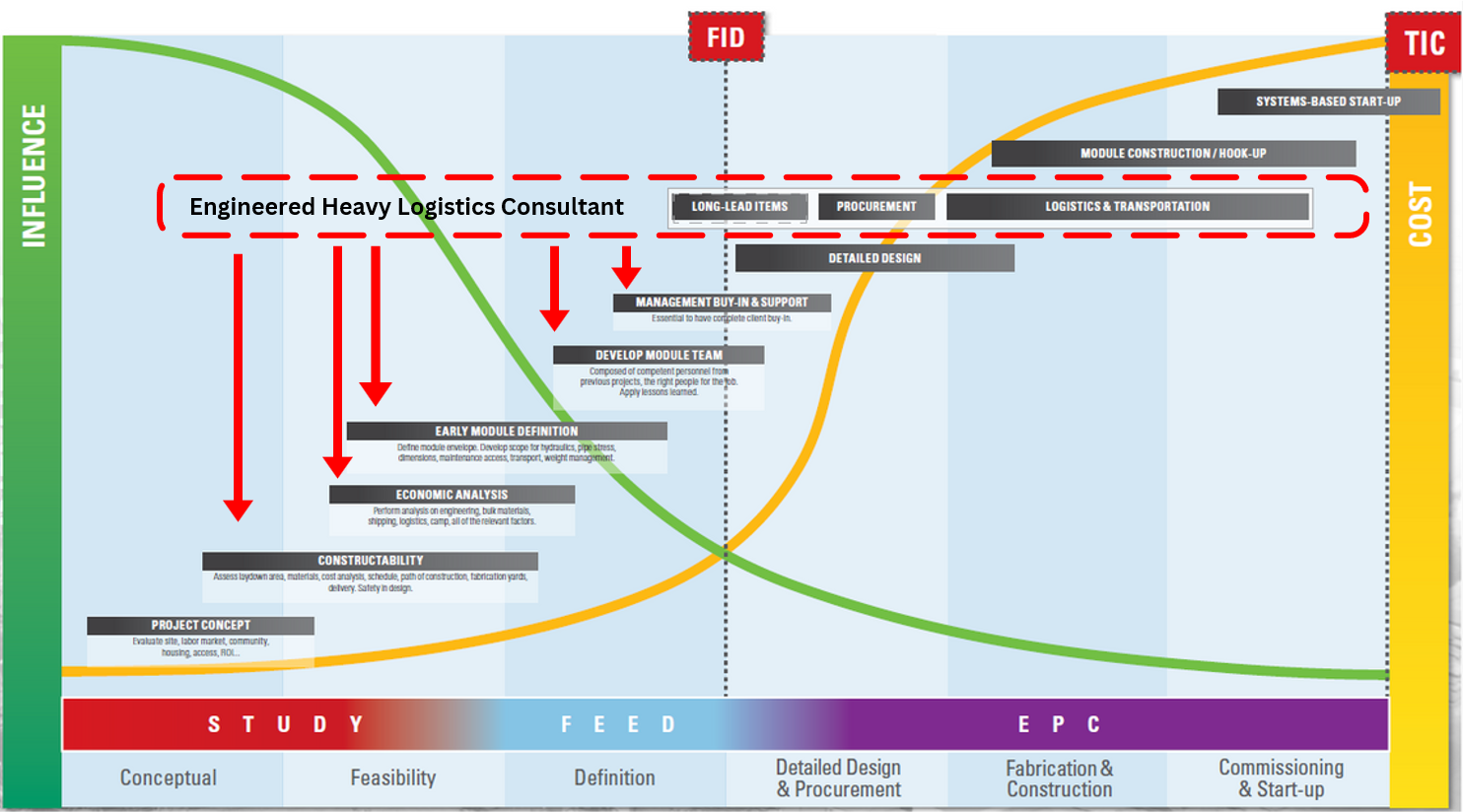

Early Logistics Engineering & Modularization Support

The Route Study Is Just The Beginning

Rohde & Liesenfeld and Greenfield Logistics' combine operational experience with independent logistics engineering and bring logistics engineering forward - before risk is locked in.

- Independent, asset-agnostic logistics engineering

- Deep execution knowledge grounded in real-world transport, marine, and modular projects

- Ability to engage under professional services without commitment to execution scope.

- Solutions designed around project needs, not fleet availability

Projects in the early stages rarely need full-time logistics support, but they do need the right expertise at the right moments. Our consultants can be engaged dynamically throughout the project lifecycle.

This flexible approach allows Owners and EPCs to access senior logistics expertise exactly when risk is highest, without committing to long-term staffing or asset-based contracts.

The Problem

Logistics Is a Critical Risk, Yet Treated as a Late-Stage Commodity

“Logistics is treated as an execution problem — even though its biggest impact is during design”.

The Solution

We combine operational experience with

independent logistics engineering

and bring logistics engineering forward —

before risk is locked in.

independent logistics engineering

and bring logistics engineering forward —

before risk is locked in.

What We Do Differently

- Independent, asset-agnostic logistics engineering

- Deep execution knowledge grounded in real-world transport, marine, and modular projects

- Ability to engage under professional services without commitment to execution scope.

- Solutions designed around project needs, not fleet availability

- Decades of global execution experience

- Deep operational credibility

- Understanding of real-world transport, marine, and heavy-lift execution

- Bridges engineering concepts with executable reality

- Embedded logistics engineering expertise

- Early-phase (FEL-1 to FEL-3) involvement

- Translates constraints into design inputs

- Turns logistics into a constructability enabler

Together We

- Translate logistics constraints into design inputs

- Turn "impossible" routes into engineered alternatives

- Align modularization, transport, lifting, and installation strategies

- Reduce budget and schedule uncertainty early — when influence is highest

Service Offer

How We do it

A Structured, Gated Approach Aligned With Your Project

What You Get

- Validated logistics baseline (“as-is”)

- Multiple engineered “to-be” solutions

- Preferred logistics strategy with decision logic

- Risk, cost, and schedule implications

- Clear go-forward execution roadmap

Why it is important to you

- Earlier risk visibility

- Better design decisions

- Fewer late surprises

- Improved schedule certainty

- Reduced logistics-driven change orders

- A smoother transition from study to execution

When to Engage Us

Our value is highest before decisions are locked in, but our support can be scaled throughout the project lifecycle:

- Concept Selection / FEL-1: Validate feasibility, identify fatal flaws, define the shipping envelope.

- FEL-2 / FEL-3 / Pre-FEED: Engineer and compare “to-be” logistics solutions, support modularization and transport strategy.

- FEED / Design Freeze: Provide independent reviews, confirm constructability, challenge asset-driven solutions.

- Pre-Execution / Procurement: Second opinions on vendor proposals, readiness checks, and risk validation before commitment